A breeding ground for French startups

Here is our favourite pick.

Founded two years ago, Feeligreen – www.feeligreen.net – was certainly the most market-ready of them, with several products already lined up. What’s more, at the time of writing, Feeligreen was expecting to close a funding round of one million euros with undisclosed venture capitalists and an industrial partner.

Based in Grasse (French Riviera), a town still considered today as the world’s capital of perfume, Feeligreen is set to revolutionize both the pharmaceutical and the cosmetic industry with an electronically controlled patch designed to actively diffuse drugs through the skin, in an ionized form.

Known as active iontophoresis, this administration method uses a direct electrical current to cause ions of a soluble substance to move across the surface of the skin and diffuse into the underlying epidermis and dermis.

Measuring about 20x20mm and only a couple of millimetre thin, the compact electronic module driving the iontophoresis seats on top of a flexible printed electronics plaster with the right electrodes in place, doubling as the drug gel carrier.

This transdermic drug delivery platform speeds up drug diffusion by a factor of 4 to 10, claims Feeligreen’s CEO Dr. Christoph Bianchi.

“For example, in the case of Lidocaine which is commonly used as a local anaesthetic before vaccination, it only takes a few minutes for the drug to be fully delivered instead of an hour ", told us Bianchi while flexing some wearable prototypes.

“Our main customers are the pharmaceutical companies which are already formulating numerous drugs for use in patches. We would sell them the flexible printed layout and the re-usable active electronic unit to speed up the drug absorption”, explained Bianchi.

“Our drug delivery platform is so effective that in the case of vaccines, it could be used in place of needles, much more cost-effective and safer as you reduce the risks of infection”, continued Bianchi, “it is just a matter of finding the right drug formulation, ionto- optimised with the right conductivity”.

Other medical or cosmetic use cases for such a patch include treatments for bedsore prevention, wound healing, anti-winkle drugs or full-fledged Botox treatments as patches instead of the injections currently requiring the intervention of a doctor.

Because the flexible part of the patch can take any shape and could be designed to wrap around large body areas, Bianchi thinks this wearable active patch could yield many innovative uses, including in sportswear to alleviate tendinitis or designed as “shapewear” for cellulitis treatment and thinning.

The electronic unit is built around an ARM Cortex-M0 core. It continuously monitors the local skin temperature and skin resistivity as well as other biometrics in order to securely dispense the right amount of current for optimum drug delivery.

“Monitoring the temperature is useful to detect any possible allergy reaction”, clarifies Bianchi, while a Bluetooth LE radio link allows doctors to check all these physiological parameters.

For quality control, Bianchi says the electronic unit and the flexible patches are all made in France, sourced from partners no further than 30km around.

Biocompatible materials are used for the flexible patches, and Feeligreen will develop custom electrode designs for different drug formulations or dispensing areas. For now, the company is hoping to manufacture and ship its product for cosmetic and non-medical applications, but in the long term, Feeligreen could license its technology to OEMs in the medical sector.

Spun-off from the French research organization CEA-LETI in 2012, Wavelens – www.wavelens.com – is sampling its MEMS-based smartphone camera optics to selected customers since the beginning of 2014.

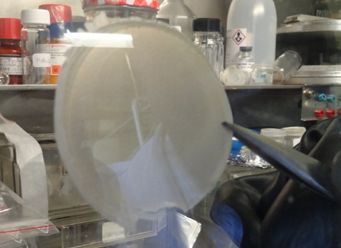

The company’s innovative optical MEMS structure comprises an optical membrane stacked on top of an optical oil-filled cavity with MEMS actuators embedded at the membrane periphery to control the oil flow (hence the membrane’s curvature and the optical assembly’s focal length).

The wafer-on-wafer collective manufacturing process flow makes these optical components very cost effective (about 1200 optical MEMS per 8-inch wafer).

Only 0.4mm in profile (the company says it could decrease the optical MEMS thickness down to 250µm), a total MEMS optics solution measuring 4.5×4.5mm2 (driver included) would draw less than 1.5mW, about a hundred times less than today’s larger micromotors solutions (typically with a footprint of 8.5×8.5mm2), yet it can deliver 10 diopters of optical power variation when driven at 10V.

What’s more, the MEMS have a response time of less than 3ms, about ten times faster than current solutions, claims Co-Founder and CEO Sébastien Bolis.

“We are aiming at autofocus applications, customer feedback has been excellent so far and we’ll be ramping up production from mid-2015 onwards with three products of different optical apertures to cover all the smartphone needs, from HD resolution to over 20Mpixels” told us Bolis at SEMICON Europa.

Wavelens is also developing optical zoom solutions but ultimately, it wants to offer optical stabilization and autofocus all in one MEMS component.

“With three micromotors, today’s optical stabilizers are overly complicated and bulky, and none of the existing solutions would be cost-competitive with our MEMS approach” said Bolis.

“With careful actuator design, we hope to be able to control the lens’ 3D shape so as to tilt the optical axis and perform image stabilization as well as autofocus, using a non-linear lens curvature” Bolis added, saying that if all goes according to plans, such a solution could well be ready by 2016.

Irlynx – www.irlynx.com – hopes to undercut the presence detection market with a very low cost uncooled infrared sensor, built from pyro-electric PolyVinylidene Fluoride (PVDF) as the underlying sensing technology and a cheap polyethylene high-density optic.

Founded in 2013 by Sébastien Fabre, the company has developed several detector arrays ranging from 16×16 pixels to more than 128×128 pixels with a thermal resolution under 1ºC and a customizable working distance (via the optics) to range from 1m to more than 15 meters.

The horizontal field of view can also be tuned through the choice of the optics, from 30° to more than 120°. Tied to an MCU, the full sensing unit offers various industrial interfaces such as UART, I2C, or SPI, the total solution fitting in less than 1cm3.

“Basically, it is PVDF spin-coated on top of an array of electrodes combined with reading circuitry”, told us Fabre, Irlynx’ CEO, “so it is completely compatible with CMOS manufacturing processes”.

The company also provides a bunch of advanced image processing algorithms to interpret the sensor’s data as presence detection, with the capability to count subjects, track their displacement, set up alarms based on posture or geo-fencing perimeters.

The company also provides a bunch of advanced image processing algorithms to interpret the sensor’s data as presence detection, with the capability to count subjects, track their displacement, set up alarms based on posture or geo-fencing perimeters.

“Our solution is several orders of magnitude cheaper than current infrared monitoring systems, and unlike camera-based solutions, we only distinguish anonymous subjects as rough shapes, hence we preserve people’s privacy”, commented Fabre.

The company had fake samples in hand, looking for the right investors to come up with the finalized goods.

A serial entrepreneur and experienced company CEO, Tristan Rousselle was presenting his new startup Aryballe Technologies, showing a poster for a handheld electronic nose capable of identifying thousands of different smells (see French startup to consumerize the sense of smell).

Although the company only has a bulky working prototype in the lab (developed at CEA-Leti), Rousselle is confident he’ll be able to shrink it and bring this e-nose to the consumer market, tentatively by 2016 (the company was founded in July 2013).

In the meantime, Aryballe Technologies hopes consumers will have fun identifying and mapping odours all over the world with the free OdoraMap app only launched last week. Later, the app will be fully integrated to the e-nose, helping the company build its database of unique recognizable scents.

A producer of cellulose-laden Li-ion battery cell separation membranes, SepCell has patented a new type of separators consisting of PolyOxyEthylene reinforced with up to 10% of crystalline cellulose nanofibers, which the company claims make the separator much stronger and more puncture resistant than expensive alternatives.

The company which has yet to be officially launched early 2015, is already working with a battery manufacturer to produce pre-series.

“A typical failure mode of Li-ion batteries is due to the formation of lithium dentrites that grow from the anode until they reach the membrane and puncture it”, explained Yannick Molméret, Co-Founder of SepCell.

“By adding cellulose fibres to the membrane, we make it about 40 times more puncture resistant than standard reinforced membranes, yet it remains lightweight and thin”, Molméret added.

On top of its 150 MPa mechanical resistance, at 60°C the membrane’s conductivity is 2.10-4 S.cm-1, better than standard solutions, hence requiring less heating to remain functional in a car battery.

In the lab, the aqueous manufacturing process yields membranes about 20µm thin, but with further development, the company hopes to reach a thickness below 10µm for commercialization by 2016. Rather than produce the membrane itself, in the future the company may well be licensing its technology to battery manufacturers.

Related articles:

French startup to consumerize the sense of smell

Europe is kicking with IT innovations and startup ideas

Emerging MEMS to drive mergers, says Yole

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News