Focusing on energy-related topics, Business Development Director Philip Pieters detailed imec’s research strategy as a roadmap to the internet of power. Pieters noted that with the democratization of photovoltaic technology, the same decentralization trend that the internet had enabled with data (generated by users locally rather than centrally controlled, and stored anywhere on portable devices) had to be replicated with the power generation industry, shifting from centrally-controlled large-scale power plants with grid balancing, to decentralized energy production by prosumers (i.e consumers with their own roof-top or façade PV installations) combined with distributed energy storage solutions.

While for decentralized energy production, imec looks into silicon and also organic photovoltaics, for distributed storage, the research centre explores electrochemical solutions for solid-state batteries.

Looking at further deployments of photovoltaic capacity in Europe, research from the European Photovoltaic Industry Association (EPIA – www.Epia.org) suggests that local PV-energy production throughout Europe would require 10% of additional PV capacity compared to a “PV in the South” approach. Yet, it would still be more efficient and cost effective to locate PV installations where consumption is located, instead of adopting a “PV in the South” scenario which would somehow “centralize” PV-energy production in the sunnier South and drastically increase total energy costs through additional power transmission and distribution lines.

Pieters highlighted that reaching grid-parity in terms of PV-generated electricity price (as it is the case in Germany for example) is not enough to make photovoltaics a winner, the cost of local energy storage has to be taken into account when calculating the levelized cost of electricity. This not only means that PV modules should output more (hence the research), it also means that localized energy storage should be implemented at very low cost.

Through the Solliance organic PV program, imec has demonstrated stacked polymer triple junction cells reaching efficiencies over 9.5%, which can be manufactured through a low-temperature solution-based process. Potentially much cheaper than silicon-based approaches, such cells would prove useful when laminated onto large building areas.

Imec’s roadmap for solid-state batteries starts from the characterisation of a planar thin-film Li-ion battery, studying one interface at a time to determine the right solid electrolyte (with high ionic conductivity but small electronic conductivity). Initial research started with a demonstration platform using a Li4Ti5O12 anode and a LiMn2O4 cathode using the respective Lithium-free precursors TiO2 and MnO2.

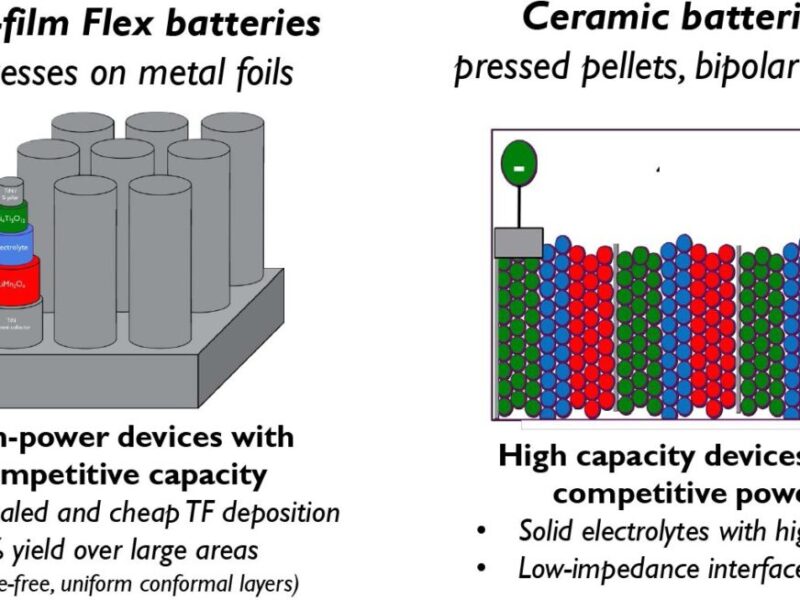

With this approach, imec plans to look into two directions, one relying on thin film deposition over metal foils (in a roll-to-roll process) while also exploring 3D microstructures (such as silicon micro-pillars) to design solid-state flex batteries. Another direction would be to develop ceramic batteries built around pressed pellets and bipolar stacks. Pieters sees 3D thin-film batteries evolve into a large area technology by 2020.

The toolbox for this research includes materials modelling to screen materials and establish physical models, but also all thin-film deposition and patterning techniques, with chemical modification processes.

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News