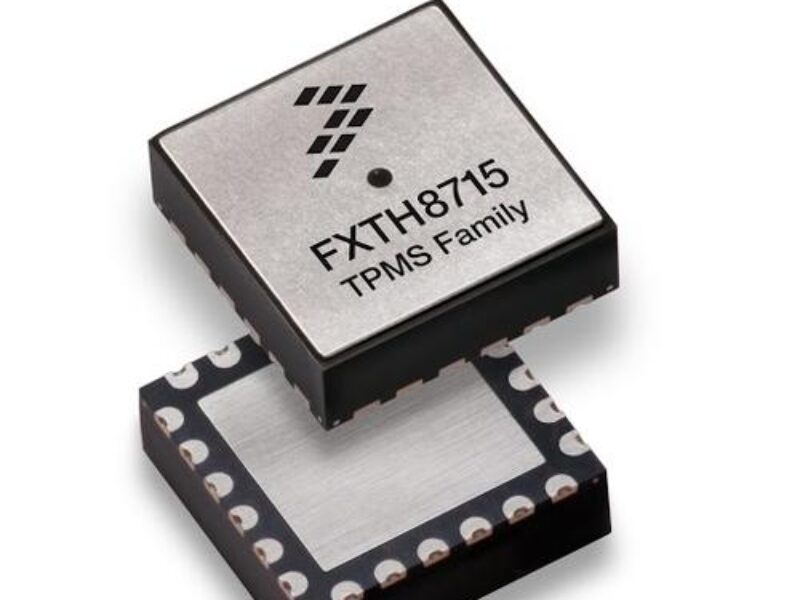

Freescale says it already has the world’s smallest MEMS tire pressure monitor for consumer vehicles, but now its upping the ante by offering the world’s highest pressure sensor for heavy trucks, buses and construction vehicles. Many tire pressure monitors use bulk machining of silicon blocks to realize tire pressure MEMS monitors, but Freescale uses standard inexpensive surface machining to realize a tire pressure monitor that uses capacitance to be much more accurate than the bulk-machined or even other surface machines tire pressure sensors, according to Freescale. Its system-in-package (SiP) also contains a two-axis accelerometer, an S08 8-bit processor with 512 bytes of RAM, 16-kbytes of flash (8k for Freescale library, 8k for applications), dedicated state machines for reduced power consumption, six general-purpose input/output (GPIO) ports — including two analog-to-digital (A/D) inputs — a low-frequency (125-kHz) receiver for programming user-defined functions and making periodic resets, and a high-frequency (315-to-434 MHz) RF transmitter supporting rolling encryption to issue warnings to the fleet manager and to read out a "prognosis" of each tire’s condition.

The built-in accelerometer turns off the device when the vehicle is sitting still, but can also record the acceleration while in motion and also includes a temperature sensor to include in the correlations. By optimizing those parameters with advanced data analytics for optimizing predictive maintenance and tracking driving behavior, the tires not only last longer, but a significant increase in vehicle fuel efficiency can be realized, less down time per vehicle and optimal vehicle usage, according to Freescale.

"We are entering the era of the smart tire — one that can tell you when and how it needs to be rotated, when it needs to be replaced and other prognostic diagnostics, instead of just telling you how much pressure it holds and when it needs to be aired up," Ian Chen, head of Freescale’s Software and Algorithms for Sensor Solutions told EETimes.

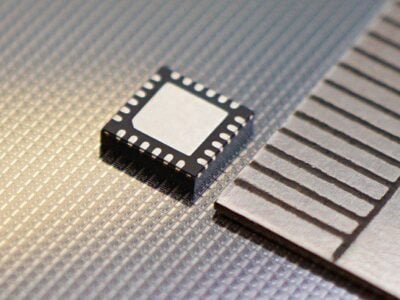

Measuring just 7-by-7-by-2.3 millimeters and weighing just .3-grams the tiny sensor can be built right into a tire by its manufacturer — making it a smart time — or can be added-on at the valve using an after market device from Advantage Pressure Pro and others. The FXTH87xx can measure pressures up to almost 217.5 pounds per square inch (1500 kilopascal second, kPs).

Accuracy is plus-or-minus 2.4 pounds-per-square-inch (psi or in metrics plus-or-minus 17kPa) operating the range of 14.5 psi (100-kPa) to 217.5 psi (1500-kPa).

— R. Colin Johnson, Advanced Technology Editor, EE Times

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News