Collaborative research programme focuses on electric motors for low carbon emission vehicles

The project, ‘Rapid Design and Development of a Switched Reluctance Traction Motor’, will also involve partners Jaguar Land-Rover and engineering consultancy Ricardo UK, and is co-funded by the Technology Strategy Board.

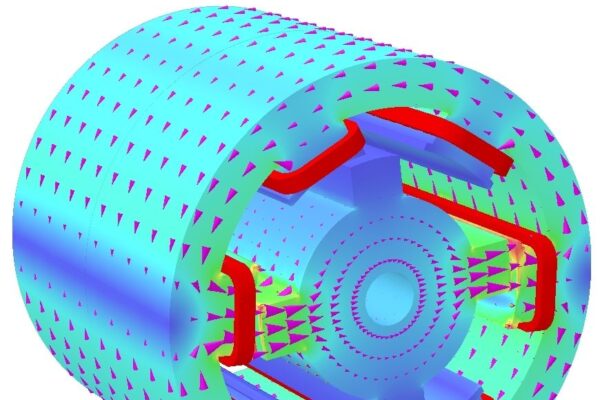

As part of its work in the project, Cobham will develop multi-physics software and capture the other partners’ methodology in order to design, simulate and analyse the performance of high efficiency, lightweight electric traction motors that eliminate the use of expensive magnetic materials. Using these new software tools JLR and Ricardo will design and manufacture a prototype switched reluctance motor that addresses the requirements of luxury hybrid vehicles.

The project is one of 16 collaborative R&D programmes to have won funding from the UK government-backed Technology Strategy Board and the Department for Business, Innovation and Skills (BIS), which have agreed to invest £10 million aimed at achieving significant cuts in CO2 emissions for vehicle-centric technologies. The total value of this particular motor project is £1.5 million, with half the amount funded by the Technology Strategy Board/BIS, and the rest by the project partners.

According to Kevin Ward, Director of Cobham Technical Services – Vector Fields Software, “Design software for switched reluctance motors is at about the same level as diesel engine design software when it was first introduced. Cobham will develop its existing SRM capabilities to provide the consortium with enhanced tools based on the widely used Opera suite for design, finite element simulation and analysis. In addition to expanding various facets of Opera’s electromagnetic capabilities, we will investigate advanced integration with our other multi-physics software, to obtain more accurate evaluation of model related performance parameters such as vibration. Design throughput will also be enhanced via more extensive parallelisation of code and developing an environment which captures the workflow of the design process.”

According to Dr Andrew Atkins, chief engineer – innovation, at Ricardo UK, the development of technologies enabling the design of electric vehicle motors that avoid the use of expensive and potentially carbon-intensive rare-earth metals, is a major focus for the auto industry.

The project has a three year timetable, at the end of which improved design tools and processes will be in place to support rapid design, helping to accelerate the uptake of this technology into production. Aside from the need to further reduce CO2 emissions from hybrid vehicles by moving to more efficient and lower weight electric motors, there is an urgent requirement to eliminate the use of rare earth elements, which are in increasingly short supply and have risen ten-fold in cost in recent years. Virtually all electric traction motors currently used in such applications employ permanent magnets made from materials such as neodymium-iron-boron and samarium-cobalt. Since switched reluctance motors do not use permanent magnets, they are likely to provide the ideal replacement technology. However, one of the main challenges of the project will be to produce a torque-dense motor that is also quiet enough for use in luxury vehicles.

Visit Cobham Technical at www.cobham.com/technicalservices

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News