Gas discharge tubes: old protection in a new bottle

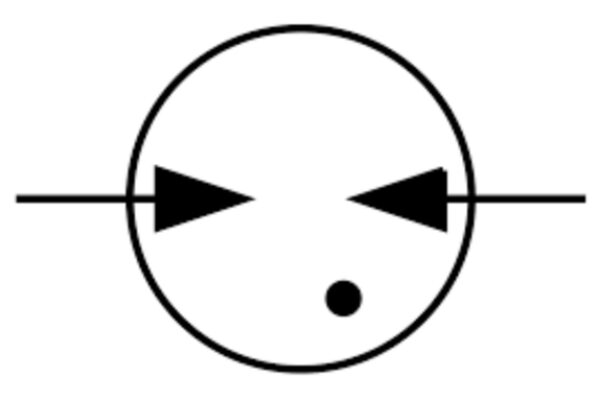

What is a GDT? In essence, it’s a sealed version of the automotive spark plug, as a spark-gap device in a sealed, gas-filled glass or ceramic enclosure, which offers near-infinite resistance across its two terminals until some threshold breakdown or ignition voltage is reached. Once that voltage is exceeded, the gas conducts (explained by Townsend discharge) and the GDT becomes a low-resistance path.

The gas in the GDT can be hydrogen, a noble gas such as helium, a metallic gas such as mercury vapor, among others, and the conducting voltage and timing is a function of the gas type, its pressure, and the distance between electrodes; early devices from the mid-1800s used air, which obviously has variability in humidity and thus performance.

In this day of semiconductor solutions to almost everything, it’s reasonable to assume that GDTs are past their prime, no new ones are being announced, and the only ones in production are for already designed-in units, until they are declared obsolete. You also might think their form factor is large, clunky, and almost “retro”, evoking vacuum tubes in their glory days.

But those are wrong assumptions, and GDTs are alive, well, and irreplaceable for some levels and classes of protection – and new ones being announced. For example, Littelfuse just released two related series of miniature GDTs with ultra-low capacitance (<0.3 pF), suitable for high-speed data links and connections, such as broadband, satellite and CATV, Ethernet (up to 10Gbps), ADSL equipment, and set-top boxes. The smaller of these surface-count devices has a diameter of just 3.5 mm; one series is rated at 3 kA (8/20 µs transient rise/fall) surge withstand capability (10 shots) while the other is rated at 1 kA with the same conditions. (Among the many other vendors of GDTs are Bourns, TE Connectivity, Epcos/TDK, NIC Components, and Phoenix Contact).

GDT applications span a wide range, such as fluorescent bulbs and neon displays, to the non-obvious but very critical roles where they are used extensively for protection against high-voltage/energy strikes such from lightning, with typical ignition voltages ranging from under 100 V to thousands of volts. Depending on design, they can handle as little as a few amps to many kiloamps. Unlike fuses, they are not one-time devices; once the triggering impulse is gone and they “recover,” they are good for another strike.

GDTS are often used in as one layer of a triple-layer protection against surges. For example, a defibrillator may need protection against surges of several hundred joules and currents of several amps, as well as other transients. This requires primary, secondary, and ESD protection using a GDT, a transient-voltage suppression (TVS) device, and ESD-protection diodes. The references cited below are just two of the many excellent, detailed ones available on the web.

Are there any other “ancient” passive devices you know which are still in widespread use, with new models being introduced?

References:

NIC-GDT-ProductTrainingNov2014R2

Bill Schweber, is an electronics engineer and author who has written for EE Times, was analog editor at EDN and prior to that worked in marketing communications for Analog Design and was also editor of its technical journal.

This article first appeared on EE Times’ Planet Analog website.

Related links and articles:

Is there still room for the vacuum tube?

Nanotechnology switches back to vacuum transistors at low voltage

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News