Obsolescence manager offers product lifecycle risk assessment

Each year thousands of individual parts and components reach the end of their lifecycle and become obsolete. EOL notices can lead to substantial costs, as it means products often have to be redesigned or reengineered. Significant product delays can also occur, as well as increased inventory sourcing and handling charges. All electronic and automation components will inevitably reach the EOL status, but how quickly they reach obsolescence can vary considerably. While many companies may have prepared for this eventuality – having built-in flexibility in their designs for example, enabling them to accommodate the volatility of component supply – there are also many at risk from the harsh consequences of obsolescence. The search for a viable replacement component can also be extremely time consuming. In most circumstances, a replacement part will need to be at least as good as the original in terms of specifications such as footprint, pin-out, power consumption and heat dissipation, among others.

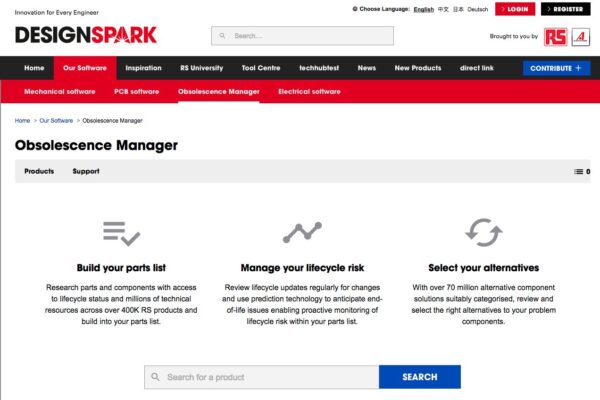

To address the challenges of component end-of-life issues, RS has developed the Obsolescence Manager, which is a completely free component-lifecycle risk-assessment tool that has been specifically designed to enable engineers and buyers to proactively monitor and manage the risks caused by obsolescence.

Initially the tool will be able to support engineers creating new electronic designs, and may be further expanded to cover the industrial sector including new panel designs and existing production-line machines.

The benefits for customers using this highly effective lifecycle management tool are many, such as being able to quickly summarise a Bill-of-Materials or parts list against a list of parts available from RS and thereby mitigate the risk of obsolescence. Customers will also be able to anticipate component end-of-life issues against predicted project timelines, as well as enabling users to find solutions for difficult-to-source parts. Overall, the tool can reduce product and manufacturing costs and ensure faster time-to-market through greater design efficiency.

The tool provides a large range of features including product lifecycle status: for example, whether components are ‘Active’, ‘Not Recommended for New Designs’ (NRFND), ‘Last Time to Buy’ (LTB) or ‘Obsolete’, as well as estimating the ‘Years to End of Life’ (YTEOL). The tool will also list parts that are alternative products in form, fit and function, as well as whether they are direct or similar replacements.

The tool’s component database will be able to access as many as 400,000 products available from the core and extended RS range, including semiconductors, passives, connectors, relays, power supplies, switches and many other electronic and electrical devices. A further 160,000 products are expected to be added by mid-2017. The dataset will also match with three million direct alternative products and 70 million functional and similar devices. The database will be updated on a monthly basis with changes logged in the system.

Visit RS Components at www.rs-online.com

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News